454 LS6 in an ’89 C4 Corvette

In my last post I mentioned some maintenance work on my daily driver, and so I thought I’d share a bit on a project I hope to complete once the new workshop is finished – my other Corvette. I picked up this ’89 in 1997 refreshed the Z51 suspension with new springs, shocks and urethane bushings, then updated the J55 brakes with cross drilled rotors and EBC green pads, and ZR1 5 spoke wheels, 17X9.5 in the front, and 17 X 11 in rear. The six speed was rebuilt, and the heavy 33 lb dual mass flywheel was replaced by a single piece unit for an ’88 that was less than half the weight, along with a different disk and pivot ball since the flywheel was thinner by about 1/2″.

In 1998, I bored the stock 350 motor .030, and added Keith Black Hyper eutectic pistons, an SLP roller cam, full roller crane aluminum rockers and new guide plates, while performing a three angle valve job and minor port clean up on the stock heads. Long tube headers complimented the SLP big mouth intake, siamesed runners and heavily ported upper plenum matched to the dual 58mm throttle body. The factory magnesium rocker covers had internal drippers that did not clear the roller rockers, so I used the composite units from an LT4 and drilled a hole for PCV. This engine ran reasonable well, but the cam I chose probably had too much duration and even with an revised ECM program, never was pleasant to drive in rush hour commutes, and the overall combination just didn’t deliver all I had hoped.

In late 2003 the throw out bearing came apart and as I was between personal garages, with all my serious tools packaged away in storage, I decided to pay a shop to replace the bearing. Taking the transmission out proved to be a watershed moment because the Y pipe was fused to the headers and the shop had to all but destroy the pipe and part of the header collectors to get the transmission out. Ordinarily, this would have just meant a side trip to a muffler shop for some fresh pipe fitting, but I had another plan in mind since my college days. Why not load for bear and swap in a fully built big blog? Here’s how this came about…

I had a well prepared LS6 454 from earlier days gathering dust for over a decade in the garage, and I decided to rebuild it and transplant it into the Corvette.

I disassembled the engine and had the block tanked, checked and honed.

I re-assembled with fresh bearings and rings. I had been running iron oval port head that had been fully ported and the bowl areas blended, but I wanted to improve performance and shed weight. I found a deal on some aluminum rectangular port heads on ebay that had been o-ringed and snapped them up.

I also picked up an arizona speed and marine tuned port injection system for the big chevy, along with the small external coil style HEI distributor for clearance. I upgraded to 36 lb injectors, and found a short style, reverse rotation water pump, along with a flat crank pulley.

So, facing the mangled exhaust on the small block, and having the fresh big block on the stand was all the excuse I needed to start the swap. Test fitting the new engine, there were three major interference points that I encountered. First, even with the flat crank pulley, the steering rack was in the way. I plasma cut the mounts, and moved the steering rack forward 1.5″ and rewelded it in place, adding some fabricated gussets on the front of the frame cross member to support the now cantilevered front mounting bolt points on the rack. An extra rag joint took care of the column spacing. We put it on the alignment rack and amazingly toe was only slightly disturbed while caster remained stable.

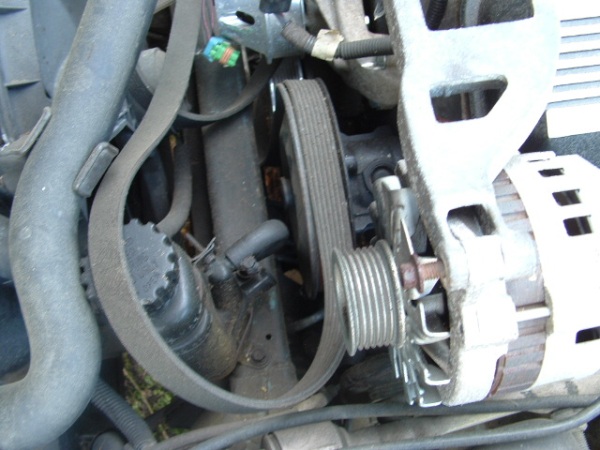

I wanted to retain the serpentine belt system, and the small block accessory brackets were useless, so I am fabricating my own – my prototype set are made out of steel, and I plan to mill some aluminum ones later. The power steering pump seen just above the alternator in the picture sits forward about 3/8 of an inch off the block face and the mounts are countersunk into a piece of plate. In a later post, I’ll show the completed brackets with some dimension and tips based on my trial and error. A gusseted riser from my power steering mount anchors one end of the factory upper alternator mount. The second interferrence point is the factory heater box – it’s fiberglass and easy enough to cut clearance relief out and glass back in the area, creating a “dent” that will clear the rear of the block and the #8 header primary tube.

The lower intake plenum, injectors, fuel rails have been installed. The intake ports that mate to the upper plenum and the distributor hole are sealed with duct tape. Alas, this project has been in limbo since early 2004 which I started work building the house as a pre-requisite to the shop, which is the pre-requisite to successfully finish projects like this one.

On the driver’s side, there is more room during the install, but not much. The windshield wiper moter must be removed from the firewall when installing the engine, but can be easily re-installed afterward. Dust, rust, and time are delaying me, bit I will see this complete.

Once mechanically complete, there will be a bit of paint and body work as well – there is a third interference in height. The big block intake is 2″+ taller than the combination it replaced, and so the stock hood must be replaced by a reproduction piece with 2.5-3″ more rise in the two center bulges. Once complete, it should appear fairly stock in outward appearance – no flames, wings or crazy paint to telegraph what lies beneath.

What should have been unrivaled five years ago is now obsoleted by the new LS7 powered ZO6 and the LS9 ZR1. Still, I expect to put down some healthy power figures and will have invested but a fraction of the $75-$130K price tag of GM’s uber vettes of today.

This thing is a BEAST. I will be around to see it come to life 🙂

I was looking for inspiration for bringing my 92 C4 into the new millennium. All I could keep thinking about was that darn power steering rack screwing me over for clearance…it looks like your work around is great! Nice job!!

Doug,

So many ways to go…supercharging may be one of the best ways – a couple weekends worth of work and you should be running strong.

Of course, building a big cube small block would be an interesting challenge, or swapping in the new aluminum LSx series could be another way.

If you are gong the big block route as I did, I might suggest building at least a 502. The new LS7 in the Z06, not to mention the 425 HP LS3’s in the new camaro and vette certainly raise the bar.

Link back with any details on your project – I’d love to see it.

Mark

Hello.

I allow myself to contact you because I wish to carry out the same project as you.

I have a big block 502 Ci with a mechanical transmission doug nash to put in my corvette of 1988.

I read the 2 main issues which you encountered but I will like to know which type of exhaust manifolds you put in your corvette.

You would have a reference and the place where had them to you, which would help me to order them in the USA.

I thank you by advance for your answers and I wish you all my wishes and full with projects for the year 2011.

Sincerely

Jean of FRANCE

water motor coil style is very clear

this water motor is the best

i have a 1984 corvette that has a four fifty four engine the headers that is on this car is rusted out can you please tell me what kind of headers that you used on your car that will work for me. please e-mail me back at hartwo48@yahoo.com thank you

Harry

If you are 454 engine lover then you will get all info,pics , 454 engine parts here

Im starting my own 454 big block drop in on my 87 corvette.

is this complete my 85 wants this 468 on my stand under its hood i have a tremis tko 500 also did you machine alum. acc. brackets do you still have a/c

What kind of headers did you use for the 454 in the 89 corvette?

have a 86 looking to install mild 454 what headers did you use? have you finished it yet?

Can u send all of your listings of parts to my emails to edwinjamessutphin@gmail.com ASAP Iam doing the same thing to my c4 88 vett

I have a nice bbc “454”65 / 69 to put in my c4 88 vett Lt1 automatic ! I am going to do a swapping out of my eng n trans .with t6060 apr heads forged pistons, rods , roller cam .650 lift n to top it off EFI WITH 8 50mm from “ Holly “EFI “base hp 750/ 1200tr ?

I too want put bbc in 95 vette Automatic would 72 vette hooker side pipes work???